technique solution

solution:

1. products processing solution

1) customer: 2) product:

3) processing accuracy: follow the drawing from customer

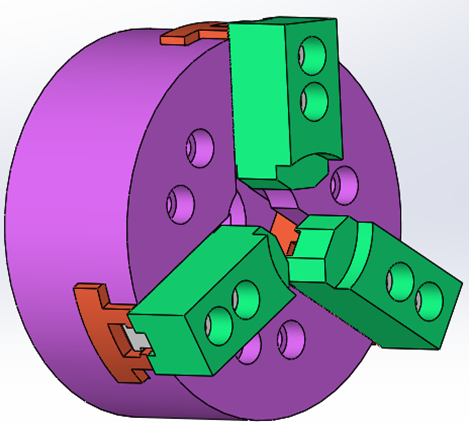

4) work tool&fixture: precise hydraulic collet

|

cnc lathe the first process--- products fixture method and process proposal |

|||||

|

machining process 1> head, od, step(rough turning); 2> head, od, step fine turning; 3> grooving for step; 4> id rough turning; 5> id fine turning; |

|||||

|

process |

tools |

process speed(r/min) |

traverse (mm/r) |

cycle time(s) |

|

|

head, od, step(rough turning) |

|

s1100 |

f0.1 |

≈40s |

0.7s |

|

head, od, step fine turning |

|

s1300 |

f0.08 |

≈36.5s |

0.7s |

|

grooving for step |

|

s1000 |

f0.04 |

≈8s |

0.7s |

|

id rough turning |

|

s1200 |

f0.1 |

≈13s |

0.7s |

|

id fine turning |

|

s1400 |

f0.08 |

≈12.5s |

0.7s |

|

total machining time≈118s |

|||||

|

feeding materials air blowing≈10s |

|||||

|

total time≈166s |

|||||

|

cnc lathe the second process--- products fixture method and process proposal |

|||||

|

machining process 1> head, od(rough turning); 2> head, od fine turning; 3> id rough turning; 4> id fine turning; |

|||||

|

process |

tools |

process speed(r/min) |

traverse (mm/r) |

cycle time(s) |

|

|

head, od(rough turning) |

|

s1100 |

f0.1 |

≈10s |

0.7s |

|

head, od fine turning |

|

s1400 |

f0.08 |

≈9s |

0.7s |

|

id rough turning |

|

s1200 |

f0.1 |

≈3.5s |

0.7s |

|

id fine turning |

|

s1400 |

f0.08 |

≈4.5s |

0.7s |

|

total machining time≈32s

|

|||||

|

feeding materials air blowing≈10s |

|||||

|

total time≈42s |

|||||

the above cycle time is based on the logic, the actual machining time can add/cut 10% as the reference,

if the machining need 5 cutters, propose to use 8 station turret.

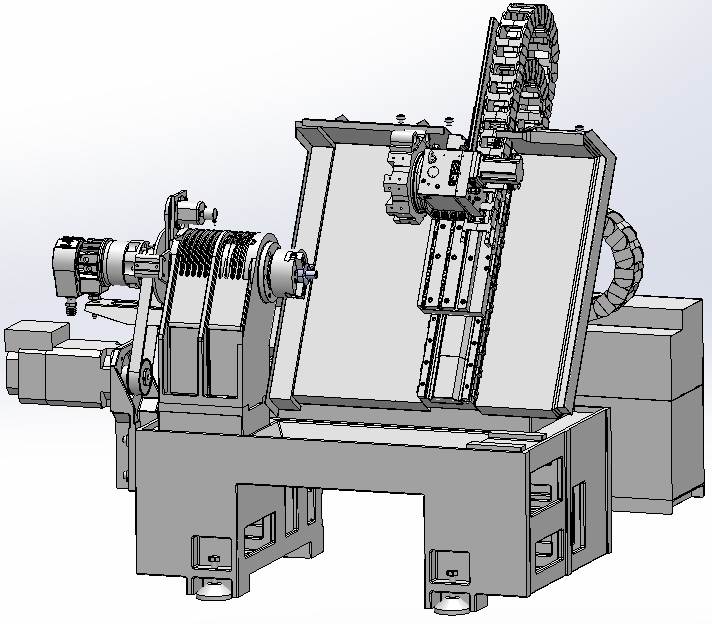

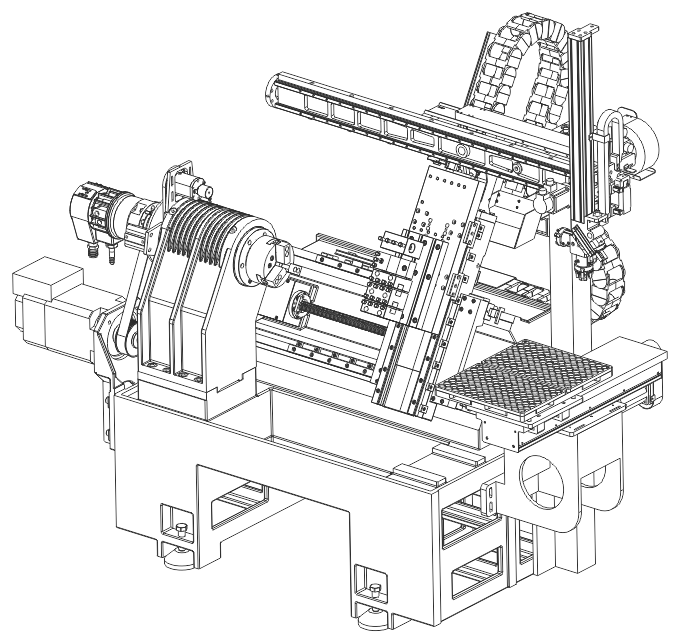

5) proposal solution:

precise linear guide-way cnc lathe with 45ºslant bed : s36 with gantry loader in tray

6) cnc lathe sketch:

1> precise linear guide-way cnc lathe with 45ºslant bed and t-slot blade row : s36( the logo

will be printed to be s36)

2> auto loader feeding system

2. parameters, configuration and price:

1) parameters:

|

main parameters |

unit |

s36 |

|

|

capability |

max. swing diameter |

mm |

350 |

|

max. turning length |

mm |

330 |

|

|

max. bar through-hole |

mm |

26(35/39) |

|

|

axis stroke |

x-axis travel |

mm |

420 |

|

z-axis travel |

mm |

330 |

|

|

rapid traverse |

x/z-axis |

m/min |

20 |

|

spindle |

spindle nose size |

n/a |

a2-5 |

|

spindle servo motor power |

kw |

5.5/7.5 |

|

|

spindle speed range |

rpm |

0~5000 |

|

|

work piece clamping method |

n/a |

homemade collet |

|

|

no. of tools |

number of tools |

pcs |

5 |

|

toolholder |

toolholder type |

n/a |

t-slot blade row |

|

opt |

t-slot blade row spindle head |

||

|

opt |

t-slot blade row 63 turret |

||

|

opt |

t-slot blade row 63turret spindle head |

||

|

toolholder center height in radial |

mm |

62 |

|

|

tool size |

mm |

20*20 |

|

|

boring rod diameter |

mm |

25 |

|

|

accuracy |

x\z axis repeating postioning accuracy |

mm |

0.002 |

|

others |

cooling motor capacity |

l |

120 |

|

hydraulic box capacity |

l |

60 |

|

|

required electric power |

kva |

12 |

|

|

height from floor to spindle center |

mm |

≈1070 |

|

|

overall size(l*w*h) |

mm |

1850*1750*1750 |

|

|

net weight |

kg |

≈2400 |

|

contact: echo.y.zhang

fax: 0574-88095075

tel: 86-18057486168

email: zhangyang@cngongtie.cn

add: no.16, gaoya road, jiangshan scientific&technological park, yinzhou, ningbo, zhejiang, china. eu r&d center: reggio emilia, italy