作为数控机床的综合型应用,基于六关节机器人的数控三机联动案例,颇具行业代表性。

今天介绍的就是宫铁s36c斜床身cnc车床,联动加工不锈钢高压喷枪零件的经典应用。

as a comprehensive application of cnc machine tools, based on the case of six joint robot cnc three machine linkage, quite representative of the industry.

原材料

材质:sus 304

material: sus 304

成品实样。

带沟槽、多台阶、内螺纹

sample of finished product.

grooved, multi - step, internal thread

自我们接到客户的样品起的第一印象是,比照图纸尺寸所需要的加工过程,将很难处理加工中产生的车屑缠绕问题。

事实上,相较于铜制品,过于复杂的外形结构对不锈钢产品加工都是一种考验。多台阶、大进深的尺寸要求,对本案例来说是一个新的研究课题。

为此,宫铁技术部深思熟虑、反复研究,最终给到了2个关键技术点:

our first impression from receiving the customer's sample is that it will be very difficult to deal with the problem of scrap iron winding in the processing according to the drawing size.

in fact, compared with copper products, complex shape structure of stainless steel products processing is a test. the size requirement of multi-step and large depth is a new research topic for this case.

finally, the technology department of gongtie deliberated and studied repeatedly, and finally gave 2 key technology points:

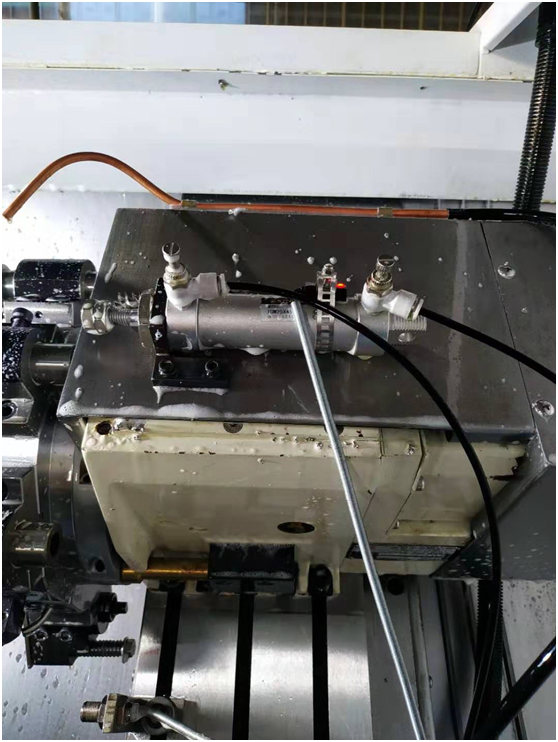

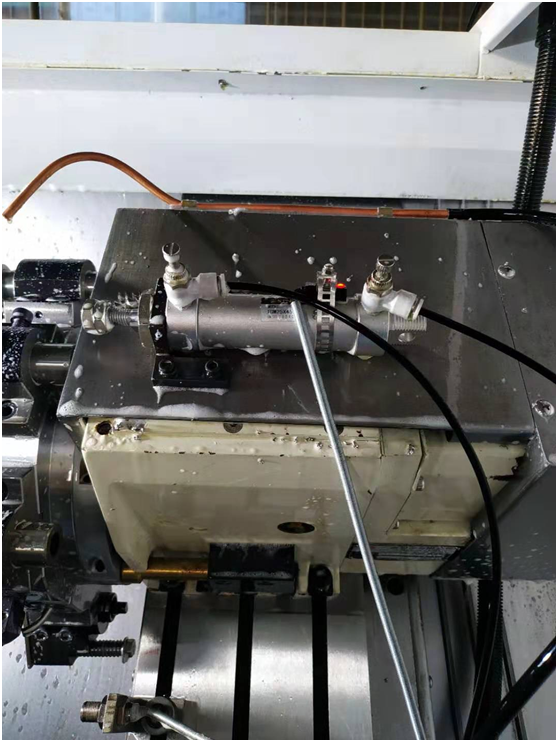

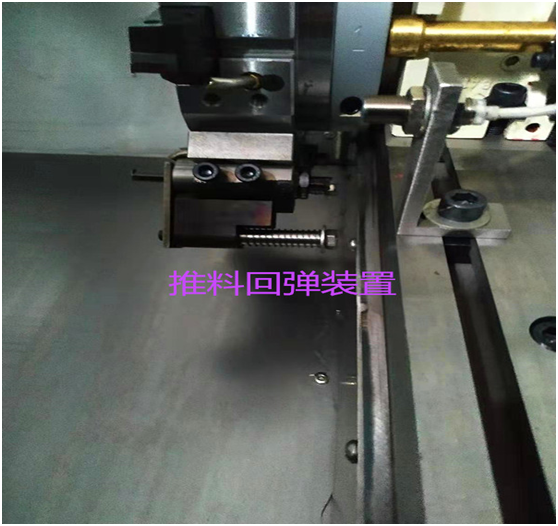

1. 经过专门的设计,在8工位液压刀塔的本体固定部位加装了辅助推波气缸;

配合位于车削刀具后方的顶出 & 弹力回撤装置,用于强制去除工件旁的不锈钢缠绕车屑,为后续加工清除障碍。

1.after special design, an auxiliary push-wave cylinder is installed in the fixed part of the body of the hydraulic turret at station-8.

with the eject-elastic retracting device located behind the turning tool, it is used to forcibly remove the stainless steel wound scrap iron beside the workpiece and remove obstacles for subsequent processing.

2. 打孔采用作息式进程。在反复多次的一进一出间获得极度顺滑的加工愉悦感。

这也为最大程度地减少不锈钢车屑的缠绕创造先决条件。

the drilling process adopts work-rest type. obtain extremely smooth processing pleasure in one in and one out repeatedly.

this also creates the prerequisites for minimizing the entanglement of stainless steel scrap iron.

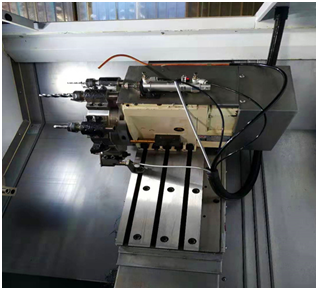

解决了车屑的缠绕问题,接下来就是根据加工要求作出联机加工的车位布局。

solved the scrap iron problem, the next is according to the processing requirements to make online processing parking layout.

1)加工过程:外圆 倒角 平头 台阶 打孔 内螺纹

2)具体加工位置:中心机床用于二次加工。侧装两台用于一次加工。

这是根据每道加工工序所需时间做出的加工节拍(processing rhythm)所决定的。

specific processing location: the center machine is used for secondary processing.two side mounted for one processing.

this is determined by a processing rhythm that is based on the time required for each processing step.

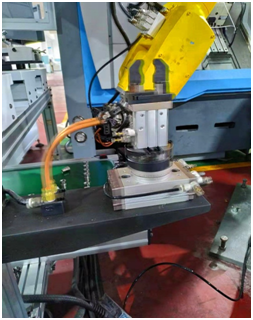

3)关节机器人按设定程序完成毛坯件、一次加工件、完成品的抓取、掉头、送料、卸料的轮换工序。

according to the set program, the joint robot completes the rotation process of blank parts, one-time workpiece processing, finished product grasping, u-turn, feeding and unloading.

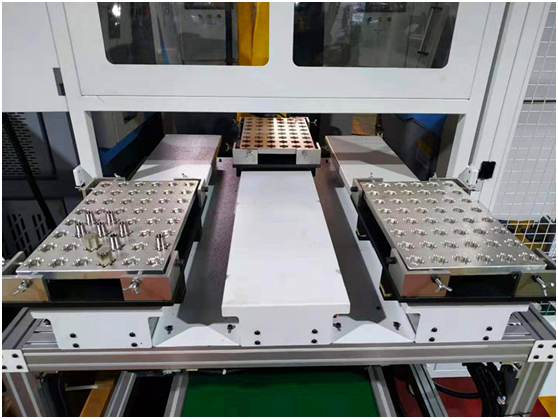

4)配备固定位置的工件掉头装置,用于工件掉头加工。

equipped with fixed position workpiece u-turn device for workpiece u-turn processing.

5)三码盘自动给料装置;六关节机器人按顺序抓取、摆放工件。

three code plate automatic feeding device; the six-joint robot grabs and places the workpiece in order

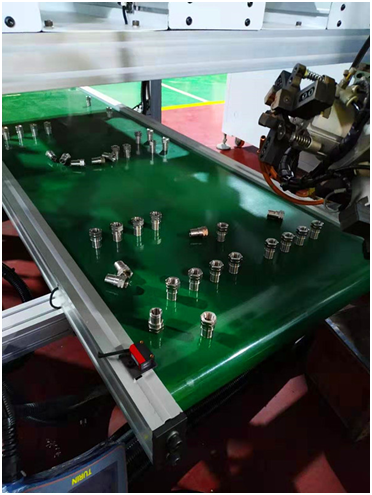

6)光电开关感应完成品的堆码情况,

the photoelectric switch senses the stacking condition of finished products

皮带机完成加工成品的自动出列;

belt conveyor to complete the automatic processing of finished products out;

成品按次序自动转到成品框内。

the finished products are automatically transferred to the finished product frame in order.

关于机器人:

about robot

1)六关节重载侧悬臂式机器人,远端载荷可达35kg。

six-joint heavy-duty cantilever robot with distal load up to 35kg.

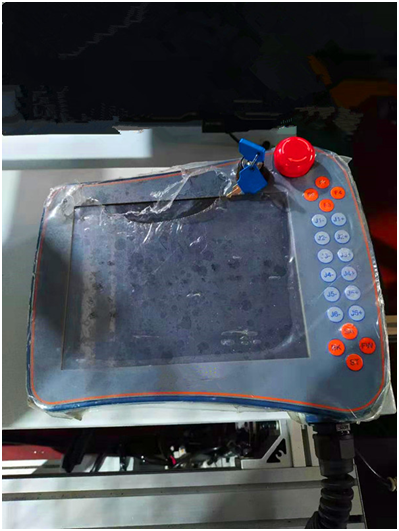

2)配备界面简洁、操作方便的手板,自学习循迹。

equipped with a simple interface, easy to operate hand board, self-learning track.

基于台达plc系统的三机和机器人协同动作控制。

three - machine and robot cooperative action control based on delta plc system.

合理的制程安排、灵活的8工位刀塔、辅助设计的车屑强制顶出和退拔装置,

在多关节机器人的自动上下料统筹下,

整个应用如鱼得水,行云流畅!

reasonable process arrangement, flexible 8-station turret, auxiliary design of chip forced ejecting and drawing device,

under the automatic loading and unloading of multi-joint robot,

the whole application like a fish in water.

contact: echo.y.zhang

fax: 0574-88095075

tel: 86-18057486168

email: zhangyang@cngongtie.cn

add: no.16, gaoya road, jiangshan scientific&technological park, yinzhou, ningbo, zhejiang, china. eu r&d center: reggio emilia, italy